PHYTOSANITARY TREATMENT

Wooden packaging materials can become a vehicle for the introduction and spread of harmful quarantine organisms and therefore pose a danger to forests on the planet as a whole.

In order to solve this problem in Europe and the rest of the world, a specific Standard (ISPM-l5) has been adopted that requires all countries to use barkwood and be subjected to approved and marked IPPC / FAO-FITOK labeling.

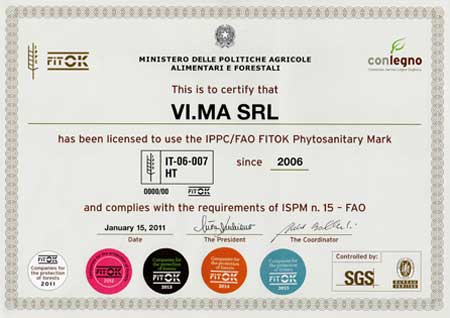

Our company was one of the first, both in Triveneto as well as nationally, to adopt phytosanitary regulations and to cooperate with the national operator of the national plant health service (Consorzio Servizi Legno Sughero). We obtained the certification in 2005 and therefore the recognition of a company authorized to use the lPPC / FAO-FlTOK label

As a reward for work and economic commitment that led VIMA Srl already in those years to invest its own money and resources in an HT treatment and drying plant. Up to today this is still the same absolute guarantee that its customers can rely on to be assured of the products' quality as well as their phytosanitary suitability.

Phytosanitary treatment has been identified as the most suitable plant protection treatment available. We have been an ambassador of this method from the very start. While our investment was rather costly, it was at the same time extremely rewarding given the associated respect for regulations and especially the environment.

As required by regulation, Vima Srl labels every single HT-treated package with a corporate identity code and number of the releasing lot on request and free of charge on a paper certificate establishing the type of treatment used, and guaranteeing the unique traceability of FITOK-labeled products.

DRYING TREATMENT

At our plant, we perform drying treatment on finished boards or packaging to meet the increasingly urgent demands of customers who need to buy wooden packaging that is free from any form of pest and mold, with a low percentage of moisture in the wood. However, all treatments are carried out according to the type and therefore the consistency of the wood to be dried, guaranteeing the structural integrity of the packaging.

RESPECT FOR THE ENVIRONMENT

The production chain was developed with all due respect for the environment.

It starts with the use of quality timber, provided by trusted European sawmills that have already processed for other uses and that originate mainly from certified FSC and PEFC forests (international bodies overseeing the intelligent management of forests around the world).

It continues with the machining of the same, using technologies that do not create noise pollution and above all does not release waste stored and stowed in containers to the environment. Instead the disposal is managed by companies who are specialized in the disposal and/or recovery of such waste. The finished product, if requested, will be treated in accordance with plant protection regulations and stored in the areas used for these products, or else it will be stored with other materials of the same nature.

At this point we have created environmentally friendly wood packaging, ready to play its role as trusted custodian and protector of the most dearest of items.